Titanium and its alloy offer excellent comprehensive performance such as excellent lightweight, good high-temperature resistance and corrosion resistance, has been originally in the Marine industry to resist the corrosion of chloride ions and micro oxidation atmosphere. Titanium alloy has better heat resistance than aluminum alloy and magnesium alloy, the working temperature can reach about 550℃. The elastic modulus of titanium alloy is about half of steel, its low thermal expansion coefficient is about 50% of stainless steel and aluminum, non-magnetic, low thermal conductivity, at the same time it has good machinability and welding performance, can be used for various parts.

Titanium has an outstanding melting point and is very corrosion resistant. It is also lightweight, making it ideal for automobile parts. In recent years, they are increasingly used in the automobile industry, which can greatly reduce vehicle weight, reduce fuel consumption and noise, and now titanium alloys are becoming a popular choice for automobile parts, from engine valves to tire rims. They are able to reduce engine weight and improve fuel efficiency while improving the appearance of vehicles. They can also reduce emissions and lower the cost of ownership for car owners. Here are some main titanium parts of automotive. Since 1956, when GM successfully developed the first all-titanium car, the demand for luxury cars, sports cars and racing cars has been increasing year by year. By 2015, the amount of titanium used in cars in the world has exceeded 5,000 tons.

| Years | Parts | Material | Company | Car type |

| 1992 | Connecting rod | Ti-6Al-4V | Honda | Acura NSX |

| 1994 | Connecting rod | Ti-6Al-4V | Ferrari | 12 cylinder |

| 1996 | Wheel bolt | Ti-6Al-4V | Polsh | Sports car optional wheels |

| 1998 | Brake pin | Gr2 | Mercedes | S – level |

| 1998 | Cylinder seal ring | 1STi | VW | all |

| 1998 | Gear changer handle | Gr1 | Honda | S 2000 live top sedan |

| 1999 | Connecting rod | Ti-6Al-4V | Polsh | CT3 |

| 1999 | valve | Ti-6Al-4V and PM﹣Ti | Toyota | Al Tezza |

| 1999 | Turbocharger rotor | Ti-6Al-4V | Mercedes | Truck diesel engine |

| 2000 | Suspension spring | Timetal LCB | The public | Lupo FSI |

| 2000 | Wheel bolt | Ti-6Al-4V | BMW | M – Techn accessories |

| 2000 | Valve spring holder | Ti-6Al-4V | Mitsubishi | 1.81 the cylinder |

| 2000 | Turbocharger rotor | γ﹣Ti Al | Mitsubishi | Lancer |

| 2001 | Exhaust system | Gr.2 Ti | General Motors | Corvett Z06 |

| 2001 | Wheel bolt | Ti-6Al-4V | VW | Sports GTI |

| 2002 | Valve type | Ti-6Al-4Vand PM﹣Ti | Nissan | Infiniti Q45 |

| 2003 | Suspension spring | Timetal LCB | Ferrari | 360 Stradale |

The Car Frame

Titanium is a good material for car body frames because of its high strength and good toughness. In Japan, car manufacturers have chosen commercial titanium welded tubes for body frames, a strong metal that allows drivers to feel safe behind the wheel.

The Engine

Titanium alloy is the ideal material for connecting rod of the engine. The connecting rod made of titanium alloy can effectively reduce engine mass, improve fuel efficiency and reduce exhaust volume. Compared with the steel linkage, the titanium linkage can reduce the mass by 15% to 20%. The first application is in Italy new Ferrari car 3.5LV8 and Acura NSX engine, the material is mainly Ti6Al4V, Ti10V2Fe3Al, Ti3Al2.0V and Ti4Al4MOSN0.5s I, etc. Other titanium alloys such as Ti4Al2S i4Mn and Ti7M4Mo are also being developed for connecting rod applications.

Titanium alloy automobile engine valve can not only reduce weight, but also prolong service life and reduce fuel consumption. Compared with steel valve, titanium valve mass can be reduced by 30% ~ 40% and engine limit speed can be increased by 20%. At present, the intake valve material is mainly Ti6A l4V, and the exhaust valve material is mainly Ti-6242S. Generally, Sn and Al are added together to obtain lower brittleness and higher strength. Mo element can improve the heat treatment performance of titanium alloy, improve the strength of hardened and aged titanium alloy and increase the hardness at the same time. Mitsubishi uses ti-22V-4Al alloy valve spring mounts in its mass production vehicles, which reduce mass by 42% compared to the original steel latch, valve mechanism reduces inertia mass by 6%, and maximum engine speed increases by 300r/min.

Ti-5Al-2Cr-Fe alloy crankshaft is being trial-produced in Japan, which has not been put into practical use due to the need for anti-bonding treatment. Other engine parts such as the rocker arm, valve spring and lower bolt of connecting rod are made of Ti-6A1-4V alloy. The free cutting ti-3A1-2.5V alloy crankshaft specially developed in Japan has been used in Honda 280 HP 3.0L V6NSX luxury racing car. Compared with the steel crankshaft with the same fatigue strength, the weight is reduced by 30% and the engine speed is increased by 700r/min. These results indicate that titanium has been accepted and used extensively in racing cars.

Spring

Compared with steel, titanium and its alloys have lower elastic modulus, lightweight and good corrosion resistance, suitable for manufacturing elastic components. Titanium springs are 60-70% lighter than steel, and in a typical American-made 5-6 seater family car, 9kg to 13.6kg can be saved by using four suspension springs. At the same time, the excellent fatigue performance and corrosion resistance of titanium alloy can improve the service life of spring.

Titanium alloys currently available for automotive springs include Ti-4.5Fe6.8Mo-1.5Al and Ti-13V11C-3Al, which were originally used in the gear suspension springs of Volkswagen’s new Lupo FSI car in Europe.

Turbocharger

Turbochargers can improve engine combustion efficiency and enhance engine power and torque. The turbine rotor of the turbocharger needs to work in the high-temperature exhaust gas above 850℃ for a long time, which requires good heat resistance, while the traditional metal such as aluminum alloy is unavailable because of its low melting point. Although ceramic materials are used in turbine rotors because of their lightweight and high-temperature resistance, their application is limited due to high cost and poor molding. Therefore, the Ti-Al alloy turbine rotor has been developed and verified by many tests, which not only has good durability and efficiency but also can improve the acceleration of the engine. This design has been successfully commercialized in the Mitsubishi Lancer Evolution series.

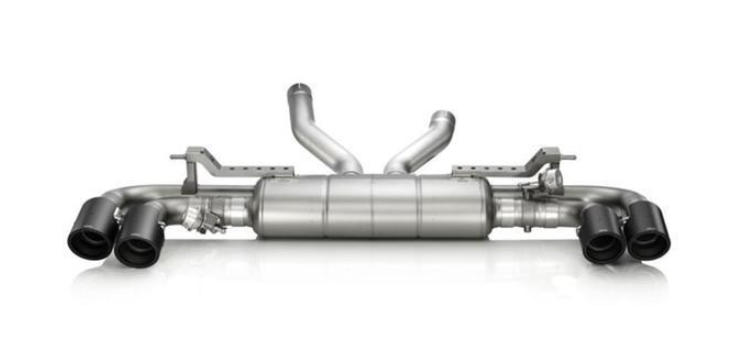

Exhaust System and Muffler

Titanium is widely used in automobile exhaust systems. Titanium and its alloy exhaust system not only improves reliability, lifetime and a good appearance but also reduces mass and improves fuel combustion efficiency. In the Golf series, the titanium exhaust system can reduce the mass by 7 to 9kg. The 2000 Chevrolet Corvette 206 uses an 11.8-kilogram titanium muffler and exhaust pipe system instead of a 20-kilogram stainless steel system. Honda, Suzuki and other manufacturers of large cars and some medium-sized cars have used titanium mufflers.

The titanium used in mufflers is mainly industrial pure titanium. Titanium tail nozzles/return assemblies are not subject to corrosion caused by chlorine and sulfur emissions from exhaust gases, and their exhaust systems are not pitted, even at the weld. Compared with the traditional exhaust system material, stainless steel, has 40% less weight, faster acceleration and shorter braking distance.

Other Titanium Alloy Parts

In addition to the above-mentioned parts, titanium is also used in other engine components, drive gear system parts, suspension systems, engine piston pin, automotive fasteners, mounting ear nuts and bolts, door protruders, retaining bracket, brake caliper piston, pin, speed change button and automobile clutch disc, etc.