Ti and titanium alloys have various and incomparable advantages such as low density, high strength ratio, good corrosion resistance, fatigue resistance and biocompatibility, which has been considered as one of the most ideal biomaterials at present and have become the clinical preferred materials for bone implantation and tooth repair. However, the elastic modulus of Ti and titanium alloys ranges from 50 to 114 GPa, of which the most commonly used Ti6Al4V alloy is 110GP, which is much higher than the elastic modulus of human bone (0.02 to 20GPa). The mismatch of elastic modulus results in poor load transfer from the implant to adjacent bone tissue, resulting in a “stress shielding” (stress shielding) phenomenon, which leads to bone absorption, gradual thinning of cortical bone and loosening of the implant, and even surgical failure. In addition, the simple mechanical bonding between the weak metal implant and human bone tissue affects the lifespan of the implant. Therefore, it is necessary to develop a new medical material that can match the mechanical properties of bone tissue and promote the growth and healing of bone tissue, and porous Ti implants, namely Ti or titanium alloy with porous structures, are becoming more and more research hotspots.

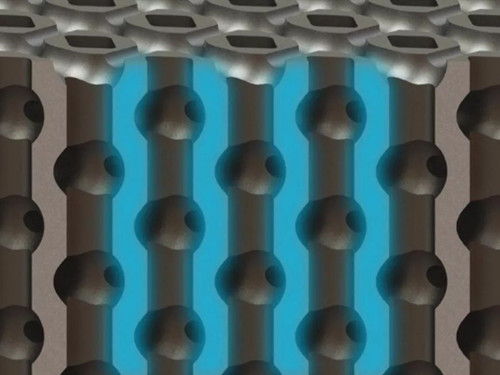

The porous structure is very similar to the microstructure of human bone and has the characteristics of small density, large specific surface area and good energy absorption. Porous titanium alloy combines excellent physical and chemical properties of titanium alloy and porous structure, which can be used to simulate the human bone trabecular structure and reduce the elastic modulus of dense titanium alloy. The unique pore structure of porous Ti and titanium alloy is conducive to the transport of body fluids and nutrients, and its rough surface is conducive to the differentiation and growth of new bone tissue into the implant, promoting the rapid formation of bone tissue inside the pore and effective link with the external bone tissue so that they improve the bond strength in the form of bone bonding. Porous titanium alloy is currently used in human bone implants, hip arthroplasty, etc., and is considered to be one of the most promising biomedical materials at present. However, there is no unified conclusion on the optimal pore size, porosity and other geometric parameters.

Properties of medical porous Ti and titanium alloys

After stainless steel and cobalt alloy, porous Ti and titanium alloy have become the third generation of medical metal materials emerging in the field of medical and clinical treatment. The excellent material for human hard tissue replacement should meet the following requirements:

- Similar mechanical properties to human bone. Mechanical properties such as elastic modulus are the primary issues that porous Ti must be considered as a substitute material for human bone tissue. It also has elastic modulus matching human bone (elastic modulus of compact bone 3~30 GPa, elastic modulus of cancellous bone 1~2 GPa) and sufficient mechanical strength (compressive strength of compact bone 0.3~1.5 MPa, compressive strength of cancellous bone 100~230 MPa). Therefore, the relationship between porosity, strength and elastic modulus should be considered comprehensively. The porous Ti alloy balances the strength and elastic modulus meets the load-bearing requirements in vivo and has mechanical compatibility.

- Good biocompatibility and bioactivity. Biocompatibility and bioactivity are the preconditions for the successful clinical application of porous Ti implants, which are conducive to the adhesion, proliferation and growth of osteoblasts, and promote the growth of bone cells into the implant to form the biological fixation between the implant and bone. The connected pore structure improves the biocompatibility of Ti implants to a certain extent, but Ti is a bioinert material, which can only be mechanically combined with the implants. Suitable chemical composition, structure and surface properties can improve the biological activity of porous Ti, which is conducive to the formation of good bone bonding between the implant and bone tissue. Therefore, surface modification is very important to improve the biocompatibility and bioactivity of porous Ti.

- Good porosity. The mechanical properties of porous Ti were adjusted by porosity, pore size and pore distribution to match the natural bone. The appropriate porosity was 50%-80% and pore size was 150-500 μm, which also created conditions for the inward growth of cells and fluid flow.

- Good corrosion resistance. The existence of pores causes complex local corrosion of porous Ti in the body fluid environment. The extremely expanded surface area increases the chance of contact reaction between the implant and body fluid, making corrosion damage easily occur. The corrosion rate is closely related to the body fluid environment, porosity, pore morphology and structure, etc. It can be seen that porosity and other related parameters are also the keys to controlling the corrosion resistance of porous Ti.

As the most potential bone repair material, porous Ti must bear certain pressure and have mechanical properties compatible with bone tissue to avoid surgical failure caused by stress concentration. Good biocompatibility and bioactivity are also necessary conditions for porous Ti to be used as orthopedic implant material.

How were porous Ti and titanium alloys made?

The three-dimensional connected porous structure is a significant characteristic of biomedical porous Ti and titanium alloys. The ideal mechanical properties and biocompatibility are closely related to the control of porosity and pore size, so the preparation of porous Ti and titanium alloys is particularly important. At present, there are many preparation methods for porous Ti and titanium alloys, including sintering, rapid forming and deposition.

The three-dimensional connected porous structure is a significant characteristic of biomedical porous Ti and titanium alloys. The ideal mechanical properties and biocompatibility are closely related to the control of porosity and pore size, so the preparation of porous Ti and titanium alloys is particularly important. At present, there are many preparation methods for porous Ti and titanium alloys, including sintering, rapid forming and deposition.

Sinter Method

The sintering method is a traditional method of preparing metal materials, which is made of metal as raw material in a vacuum or protective atmosphere through high-temperature heat treatment. The sintering method is also a common preparation method of porous Ti. According to different methods of obtaining pore structure, it can be divided into pore-forming agent method, fiber entanglement, microsphere stacking method, sponge-soaking process.

Method of Rapid Prototyping

Rapid prototyping (RP) is a method to fabricate 3D solid parts with complex shape controlled by CAD model. It is fast, accurate and can fabricate complex shape solid. It is an ideal method to fabricate porous Ti. 3D printing, gel injection shaping and other rapid prototyping technologies.

Deposition Method

Ti and titanium alloy are typical inert biomaterials. In order to shorten the healing period after implantation and improve the ability of the implant to bind to human bone, activating the surface of porous Ti and titanium alloy is an effective method. The surface modification methods of porous Ti and titanium alloy mainly include a mechanical method, physical method, electrochemical method, chemical method and biochemical method(Reactive deposition, electrodeposition, vacuum evaporation, plasma spraying, etc.).

What’s porous Ti and titanium alloys used for?

Oral and maxillofacial implants

Ti and titanium alloys are commonly used in tooth and bone repair, but their elastic modulus is still slightly higher than that of autologous bone, which limits Ti as a bone repair material.In oral and maxillofacial surgery, the application of additive manufacturing technology in porous implants and implants is still under research in general, but simulation experiments provide reliable data.

Spinal Implant

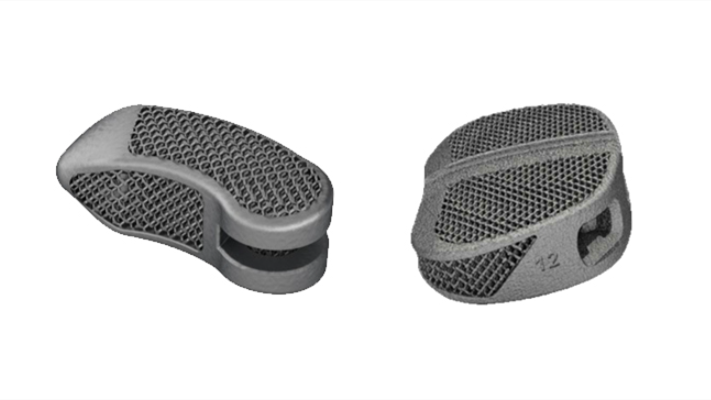

An interbody fusion device is a commonly used implant for spinal disorders that restores disc height and enables bone fusion. At present, The United States company Stryker, Nexxt Spine and Joimax in Germany have obtained marketing approval for their porous titanium alloy fusion products, which are gradually applied in clinical practice.

Hip Implant

Total hip replacement has been widely used in the treatment of femoral head necrosis, femoral neck fracture and other diseases, and is one of the most widely carried out artificial joint replacements. The acetabular cup is a commonly used hip implant. At present, a number of 3D printed porous titanium alloy acetabular cups have been registered and approved.

In conclusion, porous Ti has an absolute advantage in the field of bone repair materials in clinical medicine in the future due to its good comprehensive properties. However, the research on surface modification, bioactivation and bone tissue induction mechanism still needs to be further studied. Porous Ti with better matching of biomechanics and biological activity can be prepared by selecting appropriate preparation methods and process parameters to meet the needs of patients. The study of surface activation, induction and mechanism of porous Ti may improve the bonding strength between implant and bone tissue, shorten the period of bone integration and alleviate the pain of patients; how to reduce the manufacturing cost of porous Ti is also an urgent problem.