Biomedical metals, also known as surgical implant metals, are the alloys used for diagnosis, treatment and to replace or enhance the function of tissues in the body. Metal was one of the earliest medical materials ever used, even dating back to 400 to 300 BC when the Phoenicians used wires to repair missing teeth. In the 1930s, with the successful use of cobalt-chromium alloy, stainless steel and titanium alloy in dentistry and orthopedics, metal biomedical materials has been a hot topic in the field of surgical research. In the 1970s, the successful application of Ni-Ti shape memory alloy in clinical medicine and the development of biomedical coating materials on metal surfaces promoted the applications of biomedical metal alloys. The requirements of biomedical metal materials should be following:

- Good mechanical properties

Biomedical metal materials should generally be lightweight, have excellent strength and toughness, low elastic modulus, good fatigue resistance, creep resistance and necessary wear resistance and self-lubrication. Due to injury, tumor and other factors, bone and joint damage, it is necessary to establish a stable bone scaffold with arc plate, screw, artificial bone and joint. These long-term implants are subject to bending, squeezing and muscle contractions, and require high strength and toughness.

- Excellent corrosion resistance

The corrosion of medical metal materials is mainly caused by: general uniform corrosion: the surface of implanted materials is exposed to the human physiological environment and electrolytic action occurs; Spot corrosion caused by mixing of implant materials with impurities; Intergranular corrosion caused by different components and physical and chemical properties; Galvanic corrosion caused by a mixed use of materials with different ionization energy; Wear and corrosion between the implant and human tissue; Stress corrosion caused by stress concentration in a part of the implanted material due to load; Implant material damage fracture fatigue corrosion and so on.

- Biocompatibility

Biocompatibility is an important indicator to measure the quality of materials. It refers to the mutual tolerance and adaptation of human tissue and implant material, that is, whether the implant material will cause damage, toxicity, or other harm to human tissue. Biomedical materials should have no toxicity, no stimulation, no carcinogenesis, no mutation and other effects on the human body. No rejection reaction in the human body; Strongly bonded with the surrounding bone and other tissues, preferably chemically bonded and biologically active; No hemolysis, coagulation reaction, that is, with antithrombotic.

- No magnetism

Metal materials are not affected by electromagnetic fields and thunderstorm weather, which is conducive to human safety.

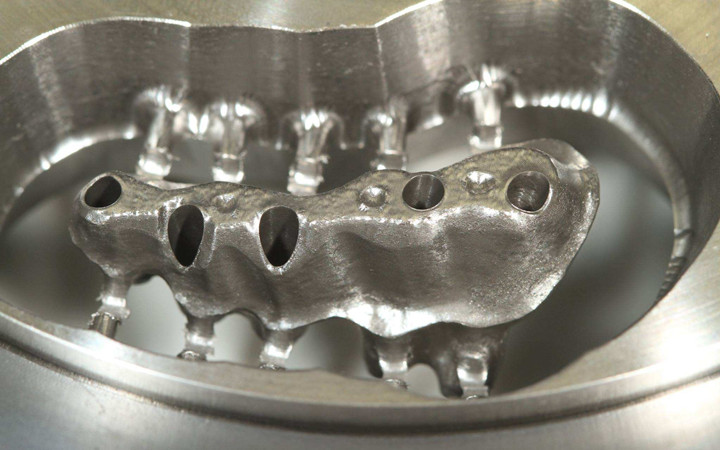

Compared with polymer materials, composite materials, hybrid and derived materials and other biomedical materials, metal medical materials offer high strength, good toughness and flexural fatigue strength, excellent machining performance and other excellent properties, which have been the most widely used implant materials in clinical application. Metal 3D printing technology has made metal medical materials more widely used, typical application components include fracture internal fixation plates, screws, artificial joints and dental root implants. At present, medical metal materials mainly include stainless steel, cobalt alloy, titanium alloy, shape memory alloy, precious metal and pure metal tantalum, niobium, zirconium and so on.

Stainless Steel

Medical Stainless Steel is one of the initially used Biomedical alloy, it is easy to process, low price, offer good corrosion resistance and yield strength and can be improved by cold processing, avoiding fatigue fracture. The most commonly used type is Austenitic Stainless Steel 304/304L, 316/316L and 317L, which are used to make medical instruments such as knives, scissors, hemostatic forceps, needles, surgical implant components such as artificial joint, fracture internal fixator, dental orthosis, artificial heart valve and other implanted devices.

The biocompatibility of medical stainless steel involves the tissue reaction caused by the dissolution of metal ions caused by corrosion or wear after the stainless steel is implanted into the human body. A large number of clinical data show that the corrosion of medical stainless steel leads to poor stability of long-term implantation, and its density and elastic modulus are far from human hard tissue, resulting in poor mechanical compatibility. Corrosion can cause metal ions such as nickel ions (General austenitic medical stainless steel contains about 10% nickel) or other compounds to precipitate into the surrounding tissues or the whole body, causing some adverse histological reactions such as edema, infection, tissue necrosis, pain and allergic reactions. These austenitic stainless steels have been gradually replaced by new nickel – and nickel-free medical stainless steels.

Cobalt Alloy

Cobalt alloy is also a metal medical material commonly used in medical treatment. Compared with stainless steel, medical cobalt alloy is more suitable for the manufacture of long-term implants for the human body environment, and its corrosion resistance is 40 times higher than stainless steel. The first medical cobalt alloy was cobalt-Chromium-Molybdenum (Co-Cr-Mo) alloy, and later forged cobalt-nickel-chromium-aluminum-tungsten (Co-Ni-Cr-Mo-W-Fe) alloy with good fatigue performance and MP35N cobalt-nickel-chromium aluminum alloy with the multiphase structure were developed and applied, which has been included in ISO5582/4. Cobalt alloy is mainly used to make artificial hip, knee, joint buckle nails, bone plate, nail and needle.

Cobalt alloy remains passivated in the human body, and its passivated film is more stable than stainless steel, with better corrosion resistance and wear resistance, with no obvious histological reaction after implantation in the human body. But cobalt alloys have inevitable drawbacks: they are expensive; Wear and corrosion cause Co and Ni plasma to dissolve and cause allergy, or cell and tissue necrosis, resulting in pain and loosening of joints. In recent years, surface modification technology has improved the surface properties of cobalt alloy and effectively improved its clinical effect.

Titanium Alloy

Titanium alloy is one of the most biocompatible metals known due to its incomparable advantages: lightweight, non-toxic, non-magnetic, excellent wear resistance and corrosion resistance. Titanium and titanium alloys are mainly used in plastic surgery, especially for limb bone and skull reconstruction, and various fracture internal fixation devices, artificial joints, cranium and dura, artificial heart valves, teeth, gums, supporting rings and crowns. The most widely used titanium alloy is а+β titanium alloy Ti-6A1-4V, which accounts for more than 80% of the global biomedical titanium alloy market, of which the strength and mechanical properties of titanium alloy can be significantly improved by gold solution treatment and aging treatment.

The density of titanium and titanium alloy is about 4.5g/cm3, almost half of that of stainless steel and cobalt alloy, closer to the hard tissue of human body, and its biocompatibility, corrosion resistance and fatigue resistance are better than that of stainless steel and cobalt alloy, making it is the best metallic medical material at present. The affinity between titanium and titanium alloy and the human body is derived from the ability to induce deposition of calcium and phosphorus ions in body fluid to generate apatite by dense titanium oxide (TiO2) passivation film on its surface after implantation, showing certain biological activity and bone-binding ability, especially suitable for bone implantation. The element V has been reported to cause malignant tissue reactions and may have toxic side effects on the human body, while Al can cause diseases such as osteoporosis and mental disorders. Therefore, biomaterials scientists are developing β titanium alloys with better biocompatibility and lower elastic modulus currently.

Zirconium Alloy

Zirconium-based alloy material is widely used as human hard tissue replacement material because of its low elastic modulus, high strength, good toughness, good corrosion resistance, non-toxic, good biocompatibility and other advantages.

Zr and Ti can dissolve into each other, indicating that they have similar physical and chemical properties. Zr is often added to Ti alloys as an alloying element to improve the mechanical properties of Ti alloys. In recent years, new biomedical alloy materials have been developed by strengthening Zr alloy with non-toxic alloying elements and optimizing its properties.

Shape Memory Alloy

Shape Memory alloy (SMA) is a new type of functional material that can undergo phase transformation under the action of temperature and stress. It has a unique Shape Memory effect and phase transformation pseudo-elasticity. It has been found that there are many kinds of alloys with shape memory effect, which can be divided into nickel-titanium alloys, copper alloys and iron alloys. Among them, nickel-titanium shape memory alloys are widely used in plastic surgery and stomatology, such as self-inflating stents, especially cardiovascular stents. The shape memory recovery temperature of medical nickel-titanium shape memory alloy is 36±2℃, which conforms to human body temperature and shows comparable biocompatibility with titanium alloy. But because nickel-titanium memory alloys contain a large amount of nickel, the nickel ions may spread to the surrounding tissues and penetrate, causing cell and tissue necrosis if the surface is not properly treated.