Titanium Grade5 is characterized by its addition of 6% aluminum and 4% vanadium, also referred as Ti-6AL-4V, is an Alpha-Beta crystalline structure. The adding of the element V and Al make it’s stronger than other commercially pure titanium while still retaining the same hardness. Titanium Grade 5 is the most commonly used alloy in Ti grades family, has been widely used in aircraft and spacecraft, marine, medical and chemical processing applications is growing. Typical applications include aircraft turbines, aerospace structural components, high-performance automatic parts, sports equipment, surgical implants and other application where light-weight, highly formable, and extremely corrosion resistant required.

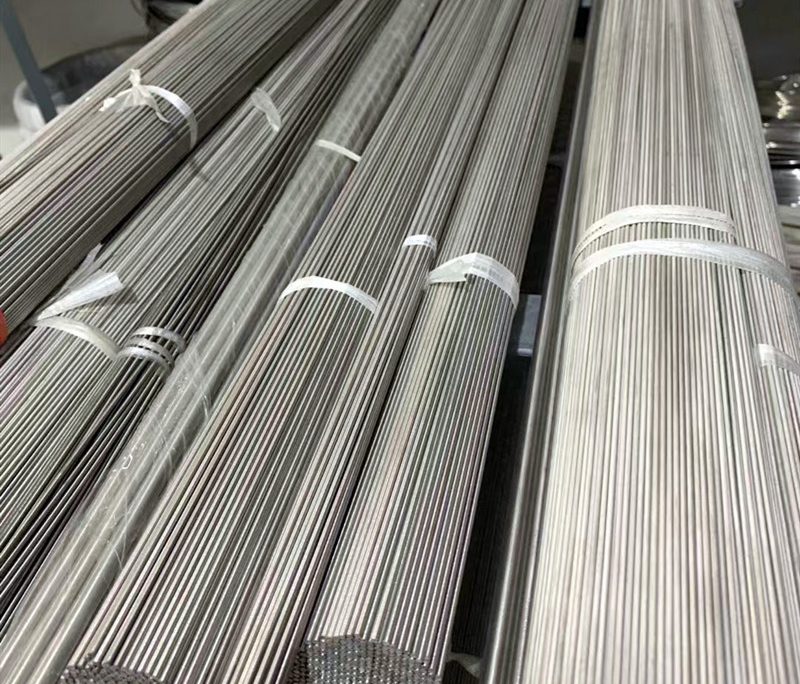

The typical applications of titanium wires were for MIIG/TIG welding filler materials, for the welding of various titanium pipes and other metals parts made of titanium. In addition, titanium wires have been used for eyeglass frames, titanium mesh filters, medical devices. At Energy Titanium, we supplied the alloyed Titanium grade 5 wire shaped of straight wires and coiled rope in accordance with ASTM B863 and AWS A5.16.

Titanium Wires Specification(ASTM B863 Grade5)

| Available standards | ASTM B863, AWS A5.16

ISO 24034 |

| Shape | Straight rods, Wire rope, |

| Size | Grade 5 : Diameter 0.1mm-7.0mm

ERTi-5:Gauge 10, gauge 11, gauge 12, gauge 14, gauge 16 |

| Surface | Descaled, Polished |

| Delivery Condition | Hot rolled, Cold worked, Annealing, Quenching |

| C | 0.08 max |

| O | 0.20 max |

| N | 0.05 max |

| H | 0.015 max |

| Fe | 0.4 max |

| Al | 5.5-6.75 |

| V | 3.5-4.5 |

| Tensile Strength, Mpa | 895 |

| Yield Strength, Mpa | 828 |

| Elongation in 4D, min, % | 10 |